By Jim Elliott, Chief Operating Officer at OTR Leasing

Keeping a truck on the road is more challenging than it has ever been. Rising fuel costs and the lingering effects of supply chain disruptions have increased costs and downtime. What began with shortages in electronic components brought on by a drought in silicon chips has moved on to availability constraints in hard goods and tires.

While there are many reasons for these disruptions, such as port closures in China, raw material shortages brought on by port backlogs, and more recently the war in Ukraine, heavy truck parts suppliers have been playing Whack-a-Mole trying to fill orders.

According to Fullbay, 82% of heavy truck repair shops have seen disruptions due to supply chain issues, with 14% reporting severe disruptions. These disruptions helped lead to an 8.8% increase in heavy truck parts pricing from the fourth quarter of 2021 to the end of Q1 in 2022 and an untold increase in vehicle downtime. The good news is that the supply chain is beginning to see some signs of stability, although some components like chip-driven electronics and tires may see lingering issues.

While large fleets can leverage their buying power to stockpile parts or to pry hard-to-find parts free from suppliers, the average owner-operator is at the mercy of the shop where their truck is being repaired or the shop’s local supplier. One may think that a way to save money in today’s environment is to forego or extend the cycle for preventative maintenance. Here are a few things to consider before delaying maintenance.

The best way to avoid time-consuming, costly breakdowns is keeping consistent preventative maintenance and avoiding the breakdown that costs you extended downtime and loss of revenue, even in these times with rising fuel prices and lower freight rates (even though freight rates are off their all-time highs, they remain well-above historical averages).

Running a piece of equipment to the point of failure can cost up to 10 times as much as a regular preventative maintenance program.

There Are Five Main Benefits To Keeping Up With The Manufacturer’s Recommended PM Program:

- Reduced downtime. No delayed or missed deliveries, and as stated above, reducing the need for expensive and extensive unforeseen repairs.

- Improved productivity and customer satisfaction. Your truck is the number one capital investment and tool for your business. Improved uptime through preventative maintenance helps ensure maximum productivity and reliability for you and your customers. Nothing can do more harm to your schedule than an unplanned breakdown from a component that lacked preventative maintenance.

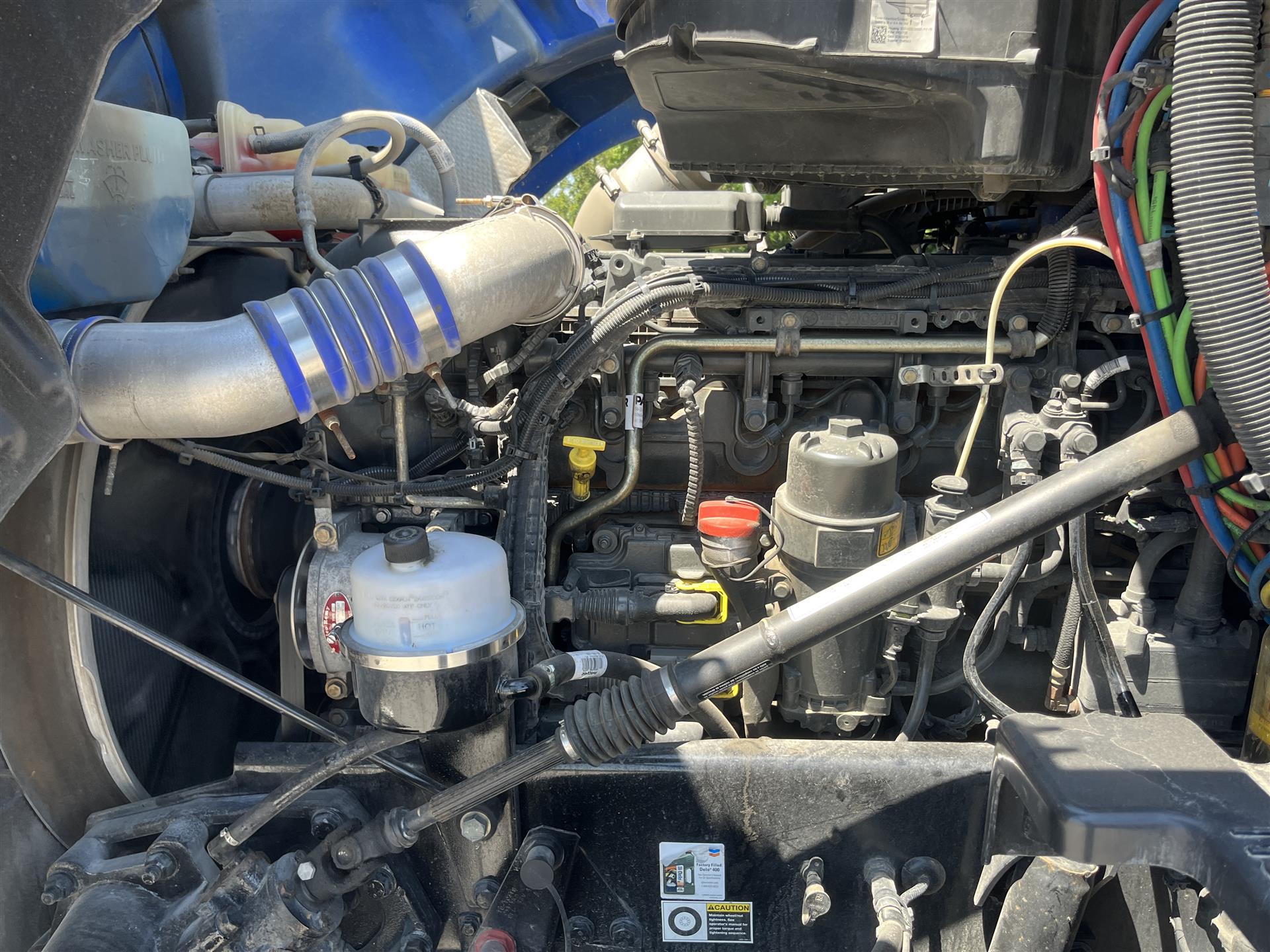

- Extended vehicle life. Maintaining your vehicle prolongs the life expectancy of every critical wear component on your truck. Engines, transmissions, differential, steering components, electrical, coupling, and HVAC systems all have scheduled maintenance that extends the life and reliability of these critical parts of your truck.

- Decreased roadside maintenance costs. Performing planned preventative maintenance gives you more control over your costs and timelines. Nothing is more damaging to your budget and schedule than unplanned breakdowns.

- Improved fuel economy. Dirty air filters, steering pivot points lacking grease, sooty oil, and underinflated tires all decrease fuel economy. At $5+/gallon for diesel, this is more powerful than ever.

While there is a lot of misinformation driving uncertainties in the trucking world today, one thing that is a given in any environment is the core importance of a diligent preventative maintenance program for your truck. Spending a little time and money today will save you money and keep you on the road in the long run.