Winterizing diesel fuel is crucial, especially in the northern United States, where cold temperatures can cause diesel to gel and impede its flow through the fuel system, affecting the operation of vehicles like trucks.

Temperature and Diesel Gelling

Diesel gelling depends on various factors, making it hard to pinpoint an exact temperature. Two critical temperature points to note are:

- Cloud Point: This is when paraffin wax starts to separate from the fuel, making it cloudy. The exact temperature varies.

- Pour Point: This is the temperature at which wax separates enough that the fuel can no longer flow. The gel point is typically 10-15 degrees below the cloud point.

Different Crude Oils

The content of paraffin wax in diesel, which solidifies at lower temperatures, depends on the crude oil source and manufacturing process. Crude oil types include Brent Blend, West Texas Intermediate, OPEC Reference Basket, and Dubai Crude.

Diesel Fuel Blends

There are two primary diesel blends: summer and winter. Summer blend gels at higher temperatures than winter blend, mixed with diesel/kerosene to lower the gel point. The more kerosene present, the lower the gel point.

Petrodiesel and Biodiesel Blends

In regions using a petrodiesel/biodiesel blend, it’s essential to note that biodiesel gels at a higher temperature. However, a mix of petro/biodiesel has a lower gel point than pure biodiesel. Both types can be treated to reduce the gel point further.

Dealing with Water in Diesel

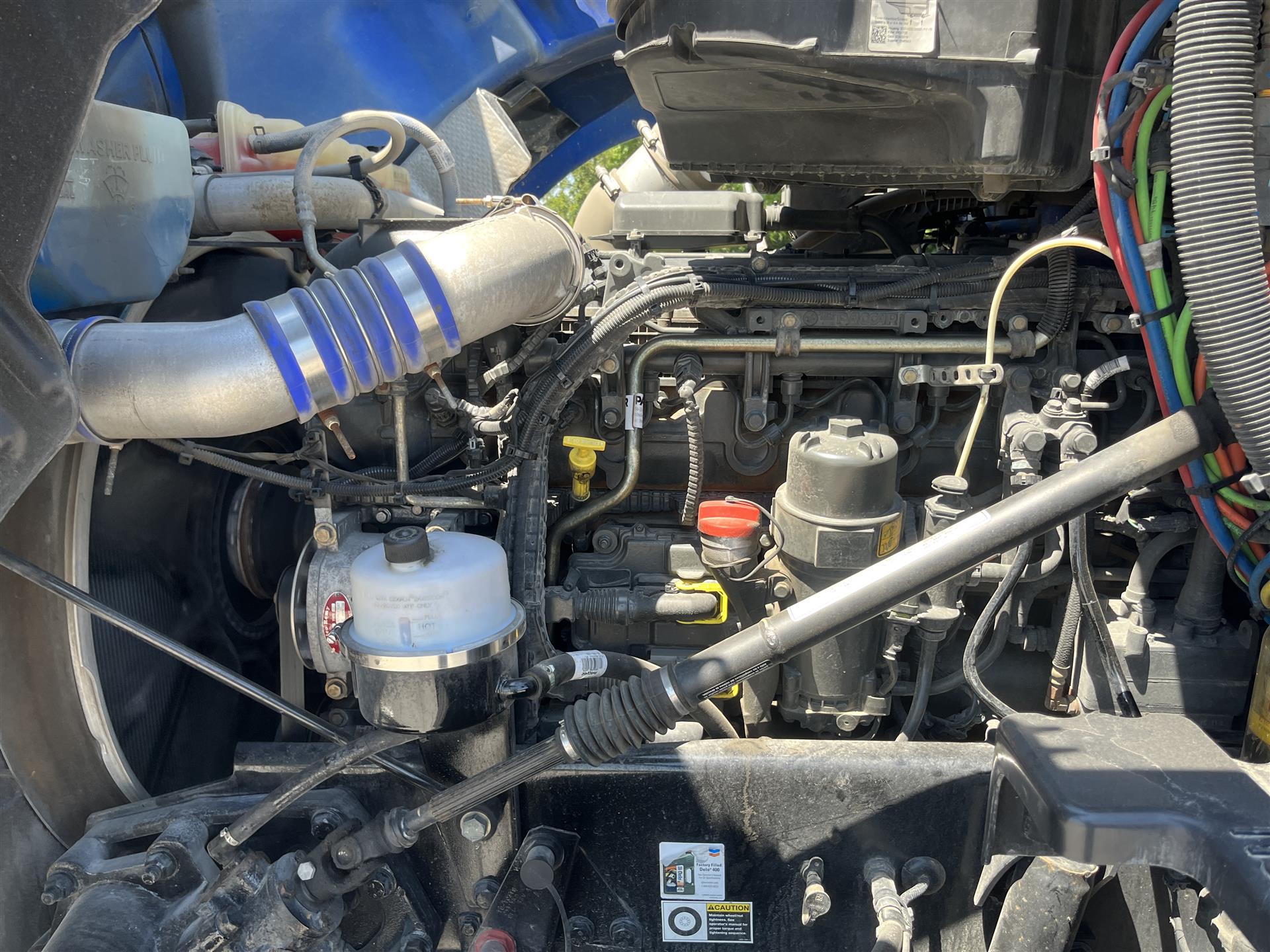

Diesel often contains water due to condensation. To maintain fuel quality, it’s recommended to use a water separator to extract water from the diesel.

Preventing Diesel Gelling

To prevent gelling, one can use winter fuel additives, which either help to dry the fuel or lower its gel point. Some additives can also thaw gelled diesel.

The Importance of Winterizing

For seamless operation in cold climates, winterizing diesel fuel is essential. This includes treating the fuel, especially when traveling from warmer to colder regions. Being prepared and proactive is key to ensuring smooth diesel flow in cold conditions.